Extend the lifetime on pipeline and wind turbines and reduce the use of resources in your company with remote monitoring of corrosion.

Assets such as buried pipelines and offshore windfarms are expensive investments and difficult to access once installed. With the rapid transformation of the energy sector including more electrification the complexity of prediction of corrosion effects increases. A powerful tool to restore control is monitoring of the actual performance, learning from data, and thereby optimizing constructions and corrosion protection.

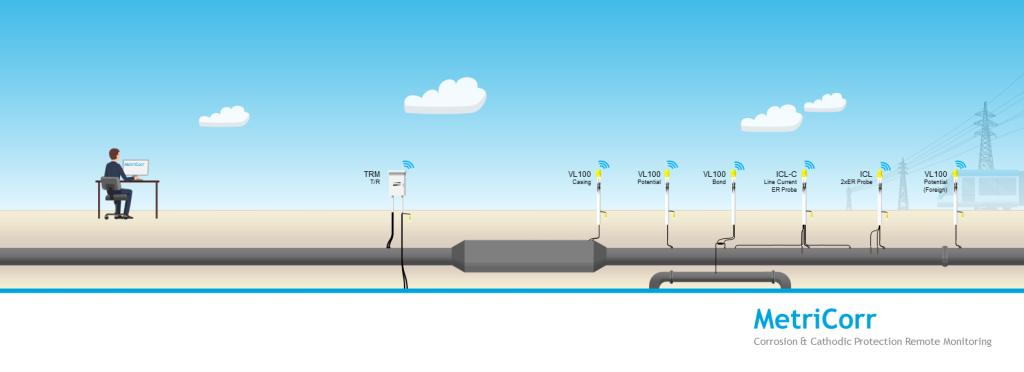

The use of real time, remote monitoring of corrosion protection performance is a digitalized approach providing better quality data. Additionally, this approach has sustainable and economic benefits such as life extension on constructions, less transport emissions and safer working conditions.

Extend the lifetime on offshore structures and pipelines

Offshore and pipeline operators need to ensure that their structures have sufficient structural integrity and are in good condition. By identifying and reporting corrosion as it occurs, operators can maintain or repair the structures in due time before the damage costs are large or the risk of failure critical. Remote monitoring solutions ensures continuous effective cathodic protection and thereby extend the operating lifetime of pipelines and offshore structures.

Reduce transport emissions and make safer working conditions

Remote monitoring of corrosion protection automates the data collection and transmission process and provides operators with reliable data. This reduces the operational inspection cost and transport emissions significantly by less frequently visits. Once installed, it helps companies getting access to critical and difficult infrastructure, such as buried gas transmission pipelines and offshore wind foundations. Additionally, this increases safety and working conditions because physical presence at locations difficult to access is significantly reduced or even eliminated.

Benefits from remote corrosion protection monitoring:

- Automate quality data collection and give early warning

- Extend the lifetime of pipeline- and offshore structures

- Reduce transport emissions

- Improve employee safety