MetriCorr provides businesses with state-of-the-art solutions for monitoring and preventing corrosion in the energy industry. But who are the people behind the solutions?

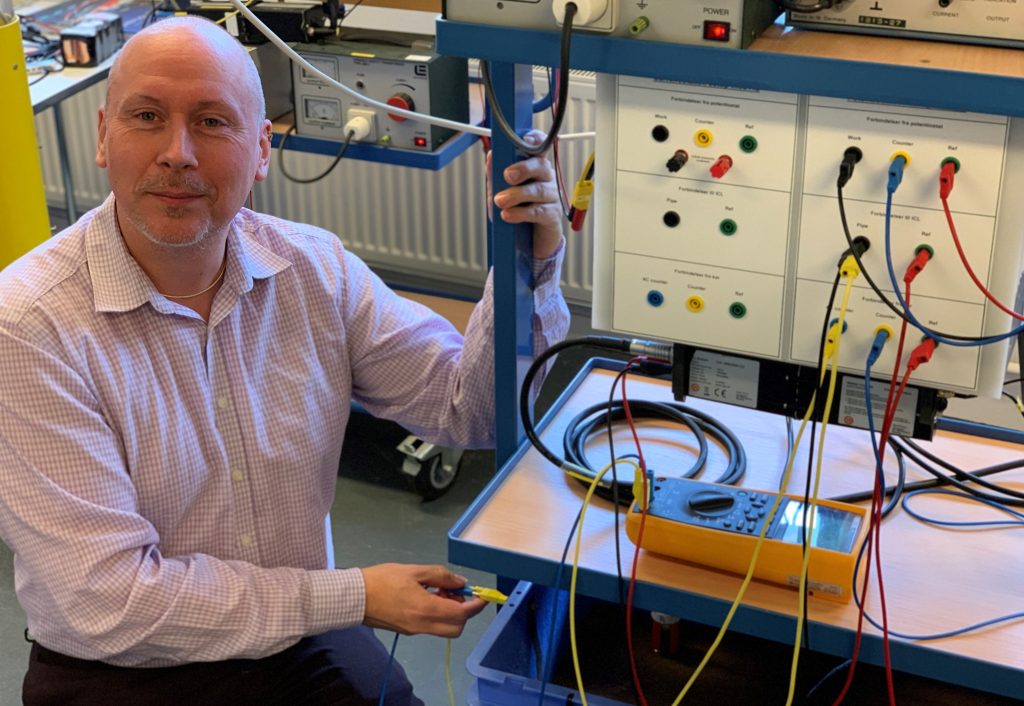

May we present one of our dear colleagues: Michael Albæk, laboratory technician at MetriCorr.

“I am very lucky to have been on the journey with Lars Vendelbo and MetriCorr since the very beginning. I have known Lars for more than 20 years, and I have never done anything else workwise, actually. Our cooperation started back when I was an intern as a laboratory technician in DTU (Technical University of Denmark), where I got offered to replace one of the employees, who had quit, when my internship ended. The employee worked closely with Lars, and as I took over her job, I eventually did the same. When Lars founded MetriCorr in 2002, I worked half of my hours at DTU and the other half at MetriCorr. As the company grew, the job became a full-time thing. And I love it here and especially the broad variety in the different tasks that I do.”

Michael is a key figure in MetriCorr, and with him being a part of the company from the beginning, he is often the “go-to”-guy, when his colleagues struggle with a task, or they have a question. Furthermore, he is an important piece in the puzzle regarding MetriCorr’s corrosion research:

“Besides being a business that provides solutions for the oil and gas industry, MetriCorr is also a company that does research within the field. Soil types can be very different from one environment to another, and therefore, we have a laboratory where we perform tests on artificial environments. In the laboratory, my role is to monitor and control the tests and keep track of them. Right now, we are doing a test on a case with severe corrosion rates, where we are trying to figure out what happens if we change different currents and potentials and perhaps divert some AC voltage.”

But Michael is so much more than the “go-to”-guy and a laboratory technician:

“I am also the company safety representative, which makes perfectly good sense with me being educated in the field of chemistry. Sometimes we handle quite dangerous chemicals in the laboratory when we are performing experiments. Furthermore, I write manuals and assembly instructions for our production team, and I have developed solar cell solutions for MetriCorr’s test stations that have been put into production. This means that customers don’t have to travel to remote places like a prairie or desert to change batteries on the test stations, which saves them time and money and the environment for unnecessary CO2-emissions.”

Even after 20 years, Michael is still very happy to be working at MetriCorr:

“I have the best colleagues. We are all very compatible and like each other, and there is such a good and relaxed atmosphere in the office. You can talk to everyone, and it is just a nice feeling to go to work. It never feels like a chore,” he explains.